Professional Manufacturer Making Metal Stamping Parts and Sheet Metal Fabrication.

WhatsApp / WeChat : +86-18636608278

Things to pay attention to when cleaning stainless steel perforated mesh

2023-09-23

Stainless steel perforated mesh has good corrosion resistance and does not need to be galvanized on the surface, so it is widely used, especially in the decoration hardware industry.Although the product itself is corrosion-resistant, it should be paid attention to when cleaning. When cleaning the perforated mesh, the wash should not contain strong acids or alkaline substances. These substances will pass through the small (invisible to the naked eye) pores of the chromium film or directly interact with other materials in the steel that have little content other than chromium to form oxidized rust.In order to ensure that the life of the stainless steel perforated mesh can be longer, some cleaning precautions still need to be understood.

The steel plate made of perforated mesh is flat and rectangular, and can be directly rolled or cut from a wide steel strip. Steel plates are divided by thickness, thin steel plates <4 mm (as thin as 0.2mm), thick steel plates 4~60 mm, and extra-thick steel plates 60~115mm. Steel plates are divided into hot-rolled and cold-rolled. The width of the thin sheet is 500~1500 mm; the width of the thick sheet is 600~3000 mm.Thin plates are divided by steel type, including ordinary steel, fine steel, alloy steel, spring steel, stainless steel, tool steel, heat-resistant steel, bearing steel, silicon steel and industrial pure iron thin plates; according to professional use, there are plates for oil drums, enamel plates, bulletproof plates, etc.; According to the surface coating layer, there are galvanized sheet, tinned sheet, lead-plated sheet, plastic composite steel plate, etc. The steel grades of thick steel plates are generally the same as thin steel plates.In all aspects of products, except for bridge steel plates, boiler steel plates, automobile manufacturing steel plates, pressure vessel steel plates and multi-layer high-pressure container steel plates, which are purely thick plates, some varieties of steel plates such as automobile girder steel plates (thickness 2.5~10 mm), patterned steel plates (thickness 2.5~8 mm), stainless steel plates, heat-resistant steel plates and other varieties are intersected with thin plates.

Stainless steel punching

Hot Products

RELEVANT INFORMATION

The Art of Precision: Exploring Advanced Techniques in Custom Metal Fabrication

2025-04-28

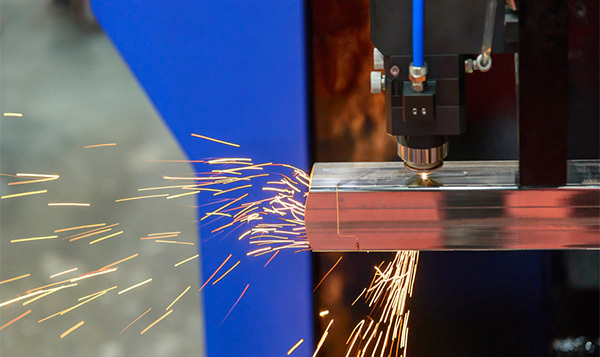

The importance of the application of laser cutting machine in the chassis electric cabinet industry

2023-09-23

A brief analysis of the wide application of laser technology in automotive interiors

2023-09-23