Professional Manufacturer Making Sheet Metal Fabrication.

WhatsApp / WeChat : +86-18636608278

The Art of Precision: Exploring Advanced Techniques in Custom Metal Fabrication

2025-04-28

YW INDUSTRIAL

Professional Engineer

Shanxi Yunwei Industrial Co., Ltd, a leading provider of precision-engineered metal components, continues to redefine industry standards through innovative custom metal fabrication solutions. Specializing in structural metalwork, stamping, deep drawing, and laser cutting services, we bridge the gap between complex design concepts and functional reality for global clients.

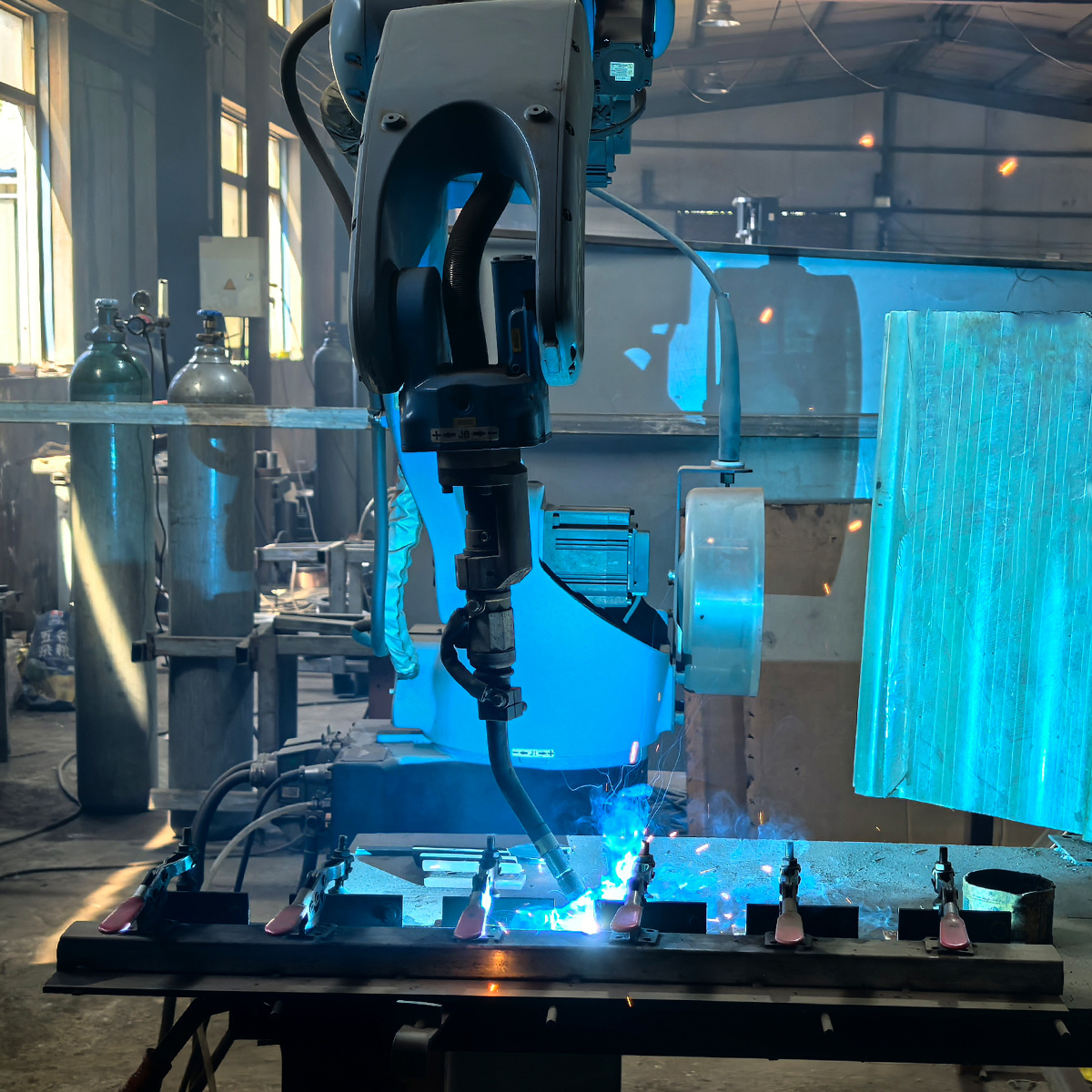

1. Structural Metal Fabrication: Building Industrial Backbones

Our CNC-controlled machining centers transform raw metals (carbon steel, aluminum, stainless steel) into load-bearing structural components with ±0.1mm dimensional accuracy. Advanced welding techniques including MIG/TIG and robotic spot welding ensure structural integrity for applications in:

-

Heavy machinery frameworks

-

Architectural support systems

-

Renewable energy installations

2. High-Speed Stamping Technology

With 800-ton servo presses operating at 1,200 strokes/minute, our stamping division delivers complex geometries for:

-

Automotive bracketry

-

Electrical enclosures

-

Appliance mechanisms

Progressive die systems achieve ±0.05mm tolerances while maintaining cost efficiency for high-volume orders.

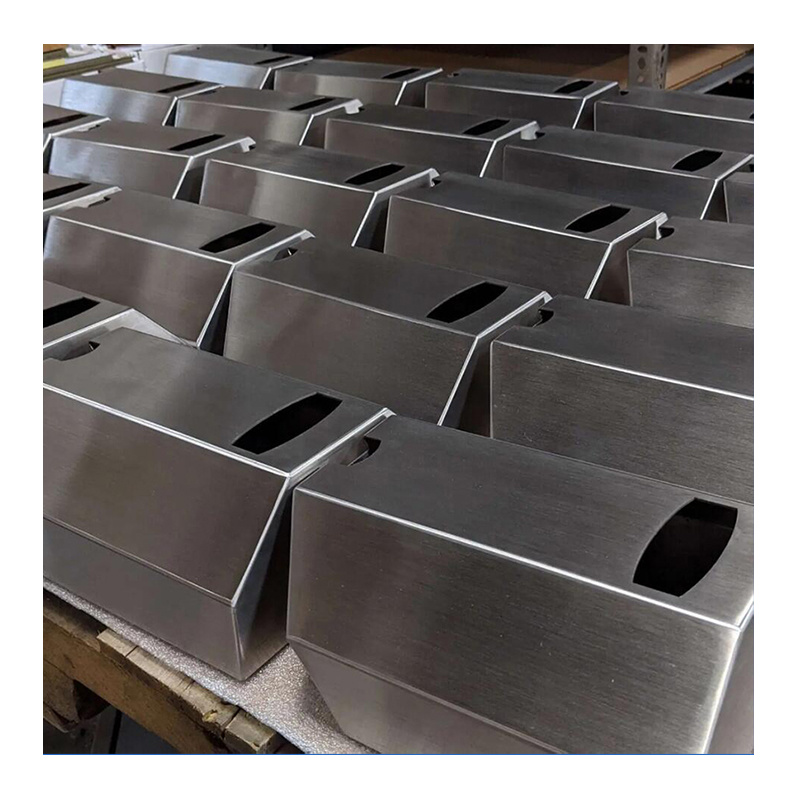

3. Deep Drawing Expertise

Our hydraulic deep draw presses (up to 300-ton capacity) create seamless cylindrical and box-shaped components from sheet metal, essential for:

-

Pressure vessels

-

Medical device housings

-

Aerospace fluid systems

Multi-stage tooling accommodates depth-to-diameter ratios up to 3:1 without material thinning.

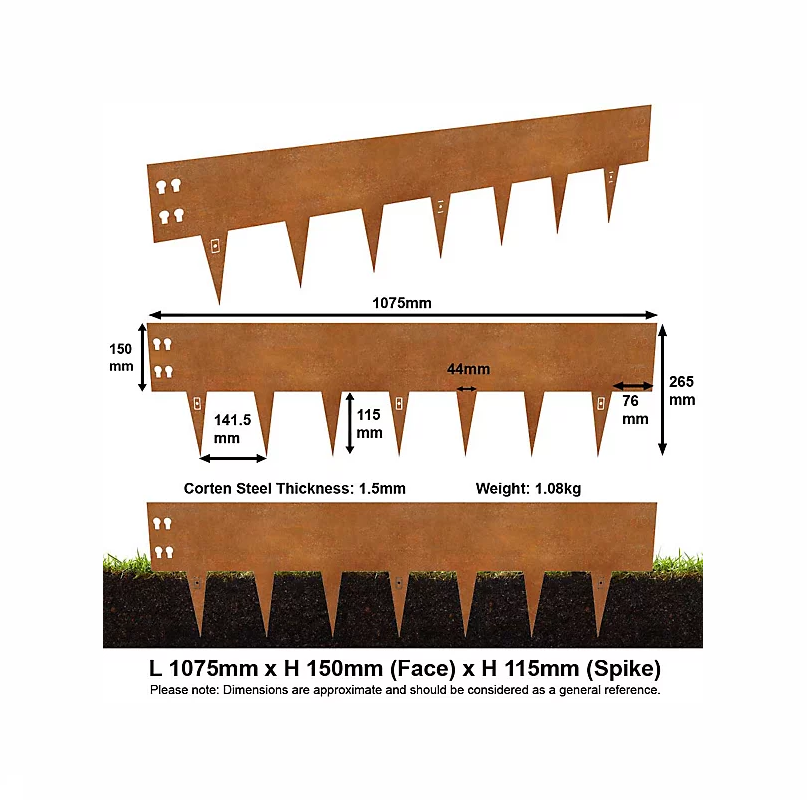

4. Fiber Laser Cutting Precision

The 6kW fiber laser system cuts through 25mm mild steel/20mm stainless steel with 0.02mm repeatability, featuring:

-

5-axis capability for 3D contouring

-

Automated material handling

-

Nesting software optimization (85%+ material utilization)

Ideal for intricate automotive trim, food processing parts, and decorative architectural elements.

Quality Assurance Framework

Every project undergoes:

-

Material certification (ISO 9001-compliant)

-

In-process dimensional verification (CMM)

-

Surface finish analysis (profilometer testing)

-

Final load testing (hydraulic test rigs)

Custom Engineering Partnership Model

Our technical team collaborates closely with clients through:

-

DFM (Design for Manufacturability) analysis

-

Prototype development (5-7 business days)

-

Small-batch production (MOQ 50 pieces)

-

Just-in-time delivery coordination

"Precision isn't just a metric - it's our operational DNA," says [Your Name], Technical Director at [Your Company Name]. "From medical-grade stainless steel to high-tensile automotive alloys, we transform specifications into solutions."

Industry Applications Served:

✓ Automotive & EV Components

✓ Industrial Machinery

✓ Energy & Infrastructure

✓ Consumer Electronics

[Call to Action]

Explore our technical capabilities portfolio or request a free project consultation:

📧 Email: Frank.y@yunwei-industrial.com

📞 Tel: 86-18636608278

🌐 Visit: https://www.yunwei-industrial.com/

Custom metal fabrication,precision stamping services,structural metal components,deep drawn parts manufacturer,industrial laser cutting company,OEM metal parts supplier,CNC metal forming,sheet metal prototyping

RELEVANT INFORMATION

China's Powerful Metal Supplier-YW Industrial

2025-07-02

About Us---Shanxi Yunwei Industrial Co., Ltd

2025-05-23

The Art of Precision: Exploring Advanced Techniques in Custom Metal Fabrication

2025-04-28