Professional Manufacturer Making Sheet Metal Fabrication.

WhatsApp / WeChat : +86-18636608278

About Us---Shanxi Yunwei Industrial Co., Ltd

2025-05-23

YW INDUSTRIAL

Maggie Yang

About Us

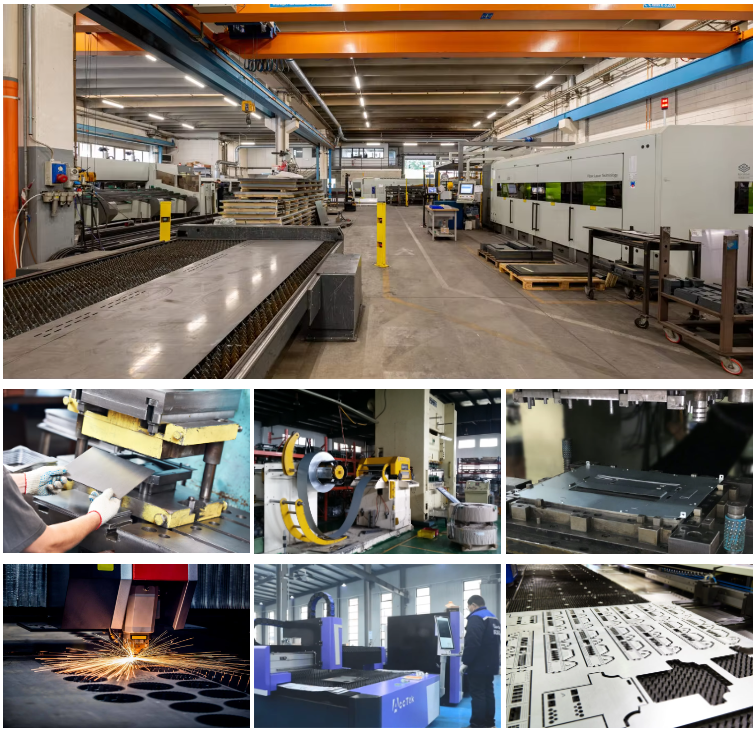

Shanxi Yunwei Industrial Co., Ltd, a professional manufacturer making metal stamping parts and sheet metal fabrication, and has 4 advanced production lines from Germany to ensure the product quality and dimension tolerance, such as laser cutting machine, CNC bending machine, CNC stamping machine,Precision stretching machine,Fully automatic pipe bending machine,Robot welding machine, CNC machining center, Fully automatic powder coating line, etc...

Our workshop has 23,000 square meters, with more than 90 employees and 4 German production lines, they are metal stamping parts production line, sheet metal fabrication production line, deep drawing parts production line and metal pipe fabrication production line. Normally, it will ship around 350 containers per year.

We have a professional R & D engineer team, and 5 engineers in it have more than 10 years of work experience. They are responsible for product design and development, which can meet all customer customized requirements;

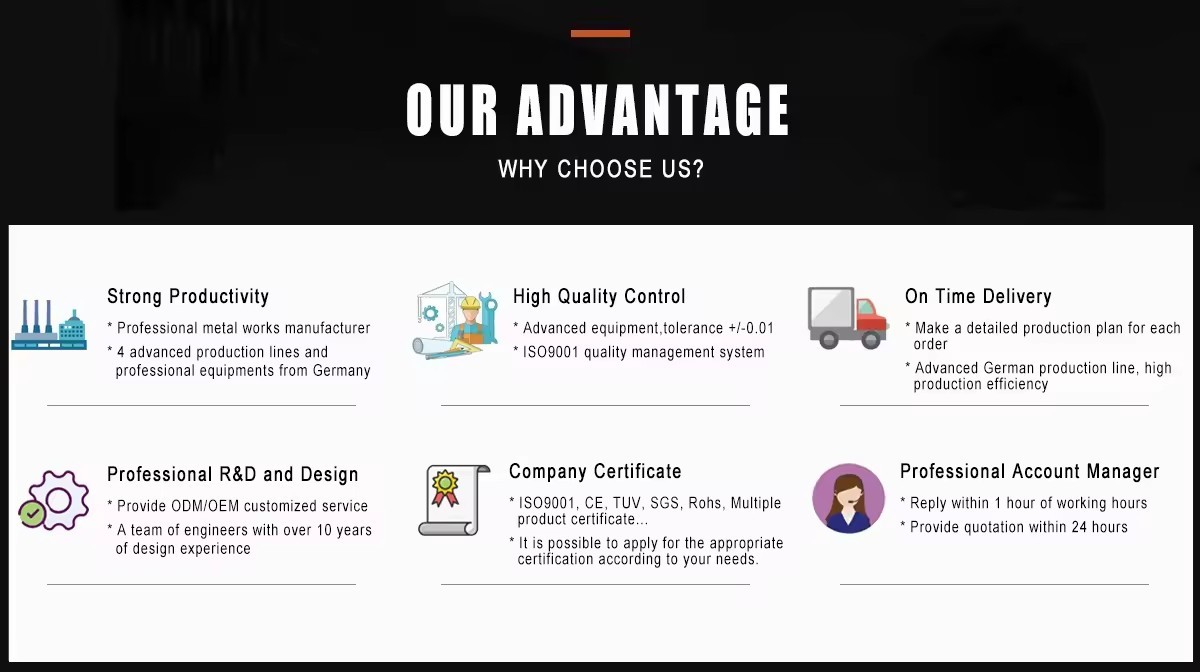

Why choose us?

● 15+ years of manufacturing experience about sheet metal fabrication, providing OEM & ODM service.

● 5 R&D engineer, 7 technical engineer, ensure product design and safe production.

● 5 QC engineer, 100% meet customers. Positive feedback is up to 99.8%

● 4 Germany production line, 150 ton production output per month, On-Time delivery is up to 98.8%

● 100% compensation for quality issue parts

● Free sample, free product design and free package design.

● ISO 9001, CE, SGS, TUV, Rohs

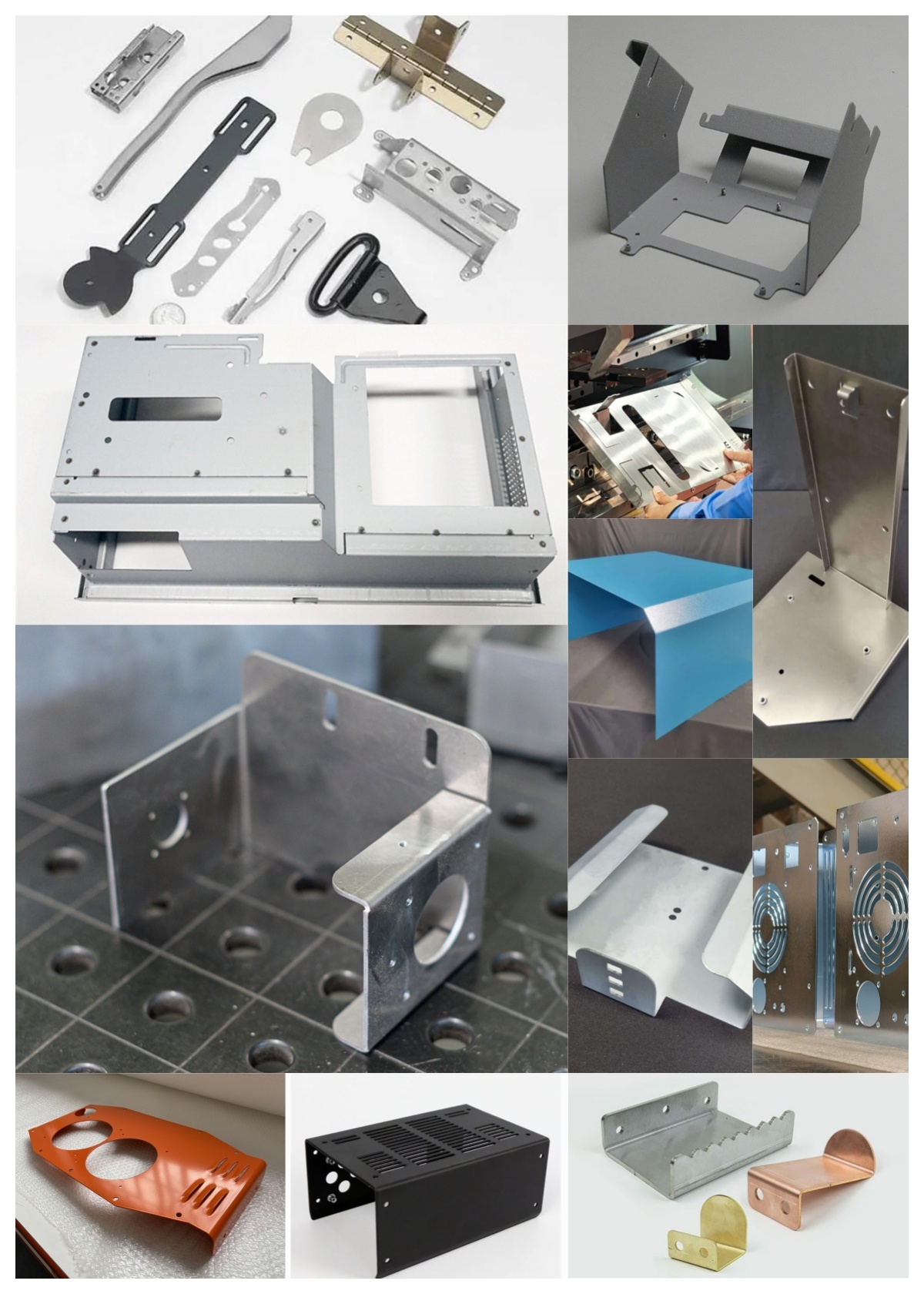

● One-stop solution for sheet metal fabrication and stamping parts

Our Team

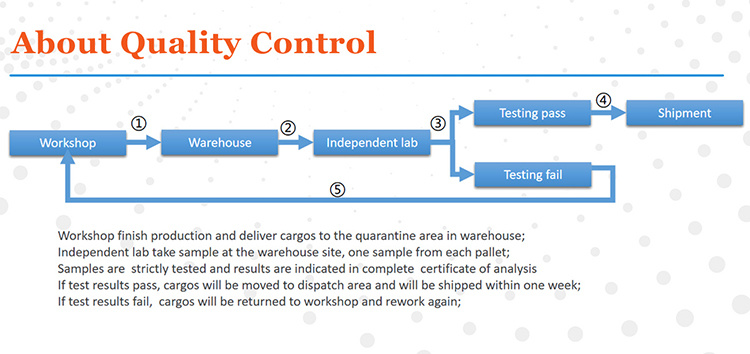

Our company has strong R&D capability and develops many new products every year. In production, we strictly follow the ISO 9001 quality system to control quality and arrange production:

1. Don’t accept defective, strict inspection of supplier's raw materials.

2. Don’t manufacture defective, the production process are strictly controlled. For all products, the workers are strictly self-inspected on each machining process, and the quality inspectors do regular inspection and spot inspection.

3. Don’t transferring defective, the defective products found in the previous process shall never be allowed to be transferred to the next process. Before shipment, the finished products shall be inspected again, and if any quality problems be found, and the products shall be reworked or rejected according to the relevant requirement.

With a group of highly professional and experienced engineers taking charge of the design, drawing draft & modification, production and quality control, we are able to meet all of our customers requirement.

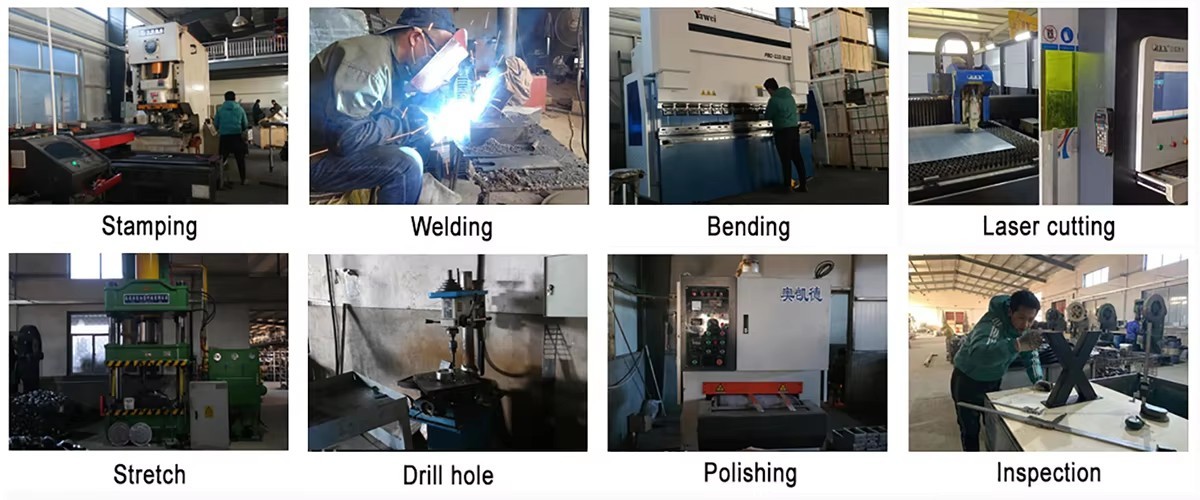

Our Factory

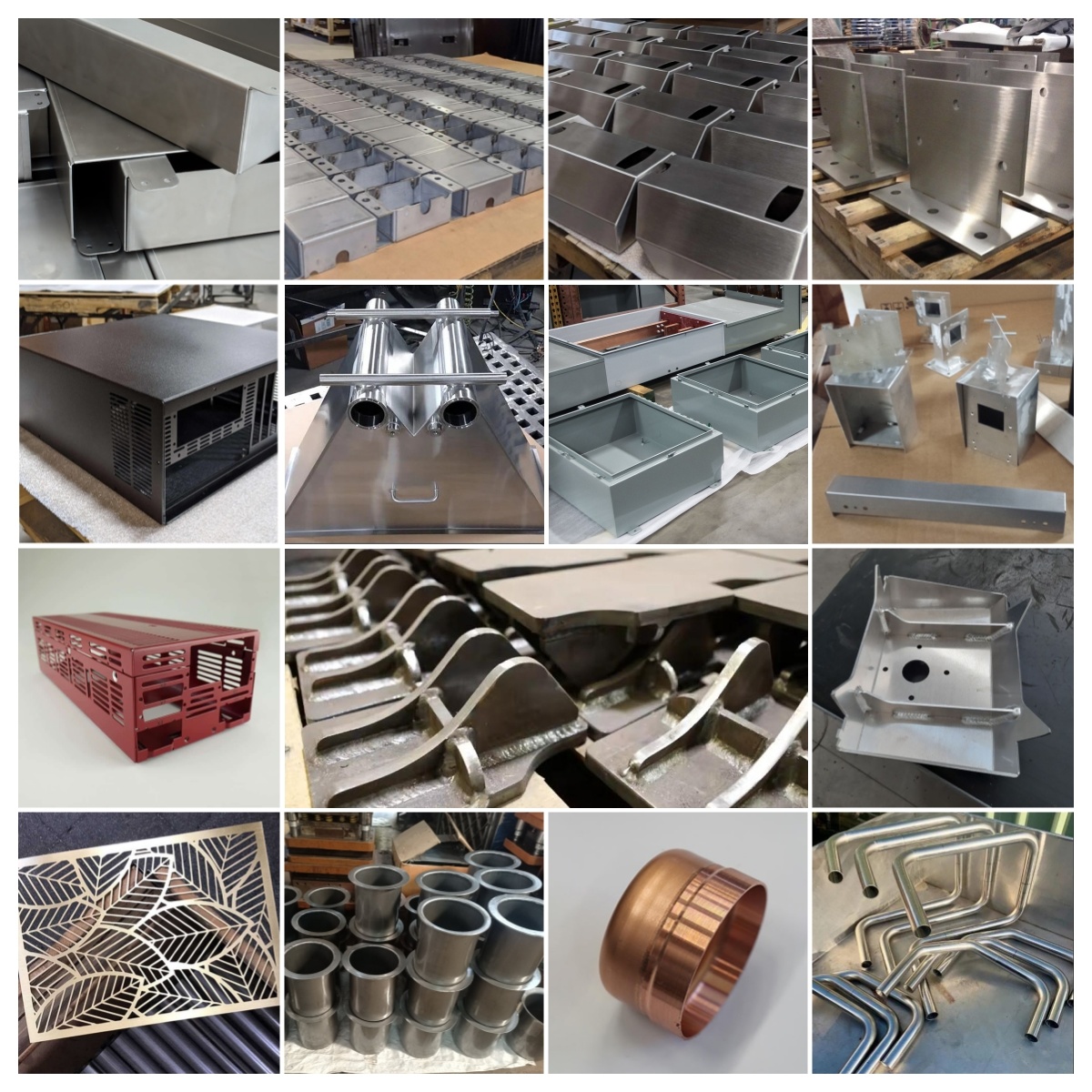

1. Structural Metal Fabrication: Building Industrial Backbones

Our CNC-controlled machining centers transform raw metals (carbon steel, aluminum, stainless steel) into load-bearing structural components with ±0.1mm dimensional accuracy. Advanced welding techniques including MIG/TIG and robotic spot welding ensure structural integrity for applications in:

Heavy machinery frameworks

Architectural support systems

Renewable energy installations

2. High-Speed Stamping Technology

With 800-ton servo presses operating at 1,200 strokes/minute, our stamping division delivers complex geometries for:

Automotive bracketry

Electrical enclosures

Appliance mechanisms

Progressive die systems achieve ±0.05mm tolerances while maintaining cost efficiency for high-volume orders.

3. Deep Drawing Expertise

Our hydraulic deep draw presses (up to 300-ton capacity) create seamless cylindrical and box-shaped components from sheet metal, essential for:

Pressure vessels

Medical device housings

Aerospace fluid systems

Multi-stage tooling accommodates depth-to-diameter ratios up to 3:1 without material thinning.

4. Fiber Laser Cutting Precision

The 6kW fiber laser system cuts through 25mm mild steel/20mm stainless steel with 0.02mm repeatability, featuring:

5-axis capability for 3D contouring

Automated material handling

Nesting software optimization (85%+ material utilization)

Ideal for intricate automotive trim, food processing parts, and decorative architectural elements.

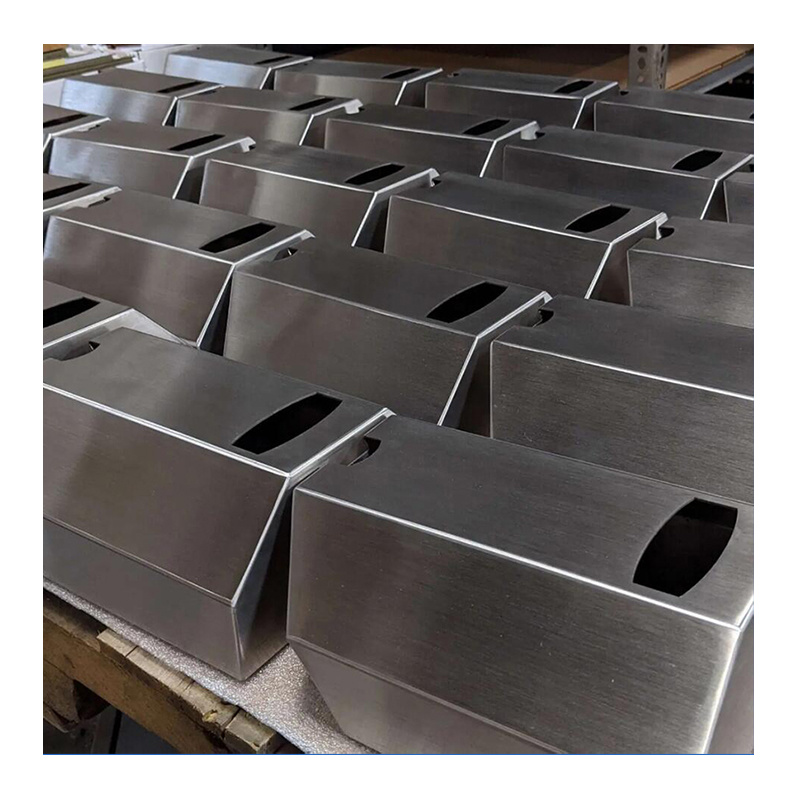

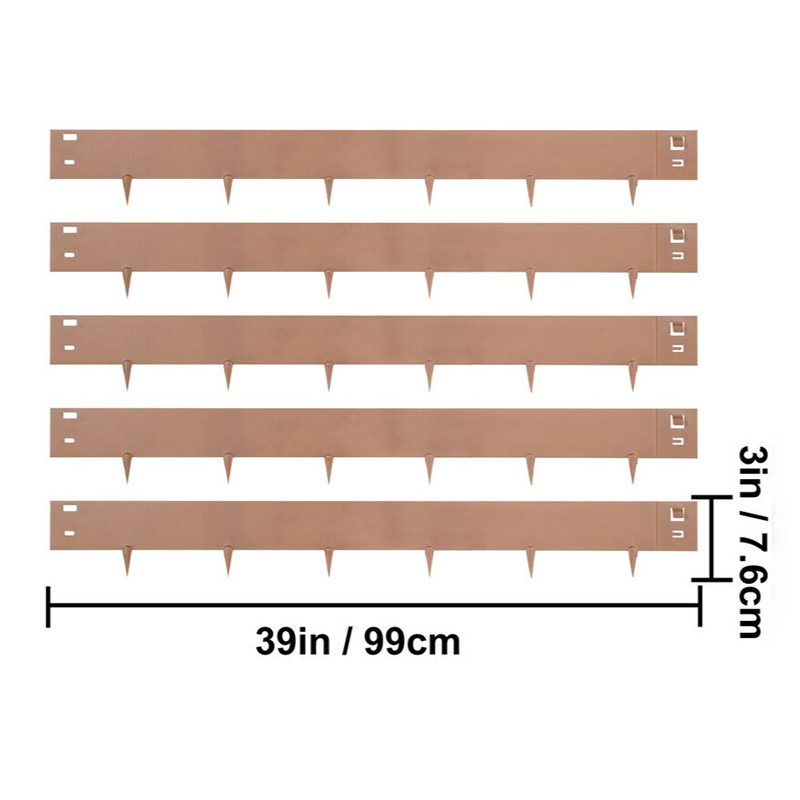

Successful Projects

[Call to Action]

Explore our technical capabilities portfolio or request a free project consultation:

📧 Email: Frank.y@yunwei-industrial.com

📞 Tel: 86-18636608278

🌐 Visit: https://www.yunwei-industrial.com/

Metal Stamping Parts,Custom Fabrication Parts,OEM/ODM Manufacturer,Laser Cutting Service,Deep Drawing Parts

Hot Products

RELEVANT INFORMATION

China's Powerful Metal Supplier-YW Industrial

2025-07-02

About Us---Shanxi Yunwei Industrial Co., Ltd

2025-05-23

The Art of Precision: Exploring Advanced Techniques in Custom Metal Fabrication

2025-04-28